Our technology

WtE have developed a solution for biochar production with focus on the need of industrial client and with using the most suitable technologies. With a unique plant design based on steam drying and high temperature pyrolysis WtE can offer a very competitive industrial scale solution with low CAPEX, low OPEX and with several revenue sources.

The carbonizer used by WtE is developed by the Japanese/Chinese supplier Benenv. Benenv have vast experience of providing carbonization plants and have well developed models for industrial use. Carbonization have been used for a long time in in Japan and China to handle organic waste streams such as sludge. In Japan it have been deployed on an industrial scale since 2002 and there are several large scale plants operational with a throughput above 60 tons per day.

WtE is the exclusive supplier of benenv’s carbonization equipment in Northern Europe and can offer a well proven technology to a competitive price. Read more about Benenv and their carbonizer on their webpage: Sludge Drying & Carbonization system (benenv.com)

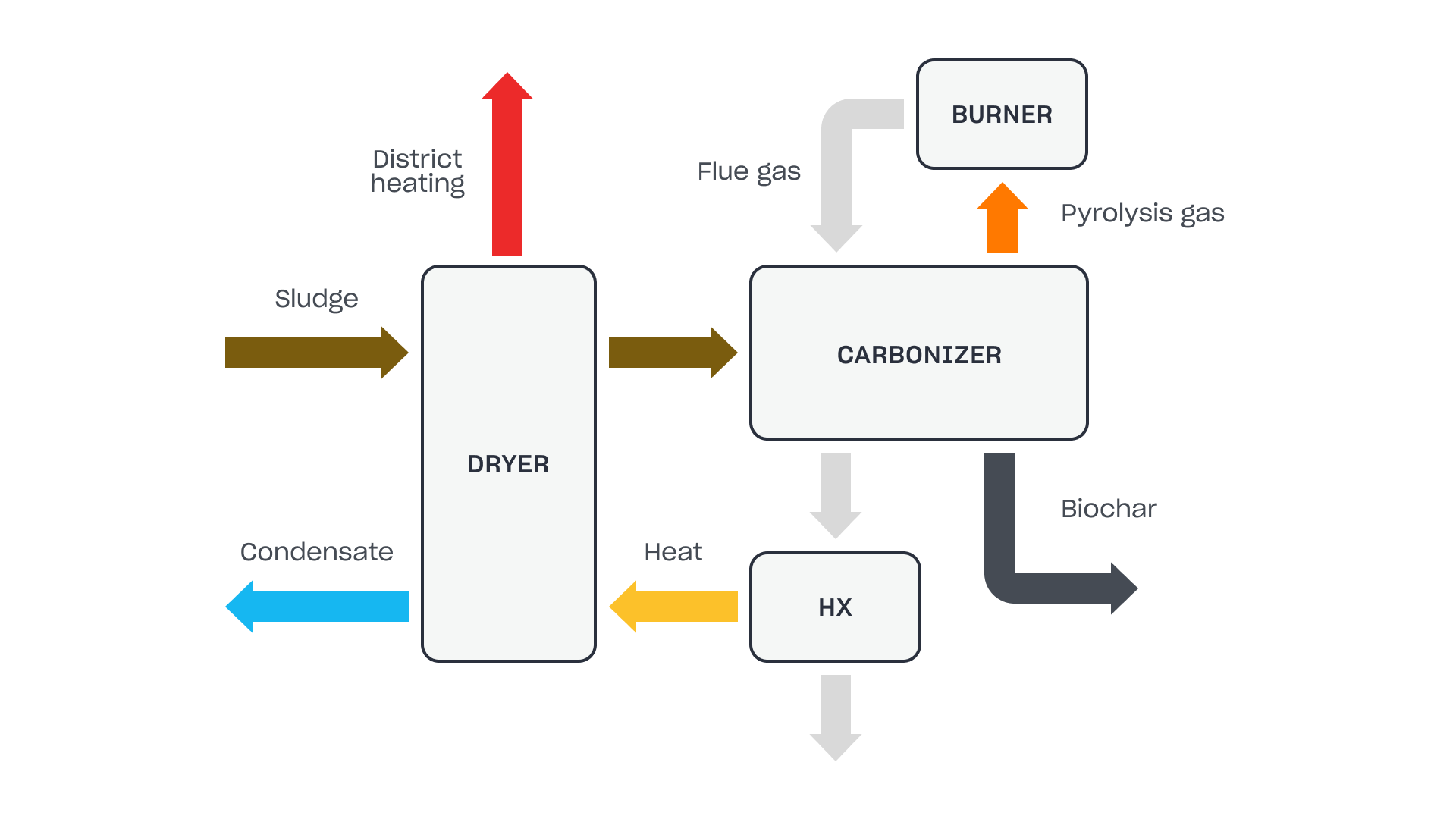

The WtE solution is combining the well proven rotating drum carbonizer from Benenv with a superheated steam dryer that makes use of the carbonizers high temperature flue gases to dry the incoming material. WtE can continuously handle large wet (25% DM).waste streams with a flow of more than 3 ton sludge or biomass per hour and with a high availability.

A superheated steam dryer can handle large flows and has a very short drying time, less than 20 seconds. It also provides condensate with a temperature above 100°C making it possible to use the heat for district heating or to produce electricity with ORC.

The combination of steam drying and high temperature pyrolysis is unbeatable since it both provides valuable biochar and heat without needing to add additional energy for drying. With the WtE biochar solution the client get a solution for a otherwise costly waste stream and a high value asset very high return on investment. It also takes us a small step closer to the very urgent need of reducing the carbon in the atmosphere.

WtE have identified the lack of industrial scale carbonization options on the European market. Unlike the Japanese manufacturer the biochar plant suppliers in Europe have not developed for industrial scale leaving the available options almost always too small to be used for industrial clients. The lack of scalability is hindering a rapidly growing market and demand for biochar. Only in 2021 the European market for biochar grew with 80% in 2021 and the carbon dioxide removal market grew with 533% where biochar holds a 40% market share.

Biochar and carbonization is today the only mature solution for removing carbon dioxide from the atmosphere. And contrary to expensive carbon capturing technologies biochar production actually produces several potential revenue streams. It is also much easier to store the carbon and many available application such as soil improvement or concrete additive.